© Website by Tooling Research Inc.

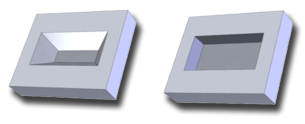

EXAMPLES OF FEATURES REQUIRING EDM OR BROACHING:

From left to right:

Tapered pocket with no radii requires EDM to produce

Straight side pocket with no corner radii requires EDM or broaching to produce.

When designing in any 3D modeling program, it is easy to get carried away with the simplicity of creating parts containing chamfers and radii on every

edge, corner and face. But think about whether or not they are really necessary. Every feature added to a part also adds to the cost. It is less expensive

to fillet a corner where two planes meet on a perpendicular plane. It is more expensive to fillet a face where the two planes contain contours or are

not perpendicular, such as when an angular face and a perpendicular edge intersect. Be prepared to pay for the 3D machining operations that will be

required to create those types of irregular features. In the case of intersecting holes we quite often see heavy internal fillets called for on the edges

where these holes intersect. Often the only way this feature can be accommodated is by some sort of hand finishing. Only spec them in if you

absolutely can not do without them.

Basic features:

When creating basic features such as drilled holes, depth and hole straightness will impact cost. Other considerations are very deep holes with small

diameters, extreme straightness requirements, and off-center intersections with other holes or features. It is hard to say just when a hole becomes

too deep for its diameter to make regular drilling impractical. Much depends on the nature of the material being drilled, and other contributing

factors such as those mentioned above.

Irregular profiles on components are no longer the problem they used to be before the advent of CNC machines but there are still some things to

consider when designing parts with such shapes.

One of the most important considerations for designing irregularly shaped parts is how the edge profile will be treated. Will it require a fillet or

chamfer, or will it just be left sharp?

Think like a machinist when creating solid models page 5

PAGE 5

© Website by Tooling Research Inc.

Think like a machinist when creating solid models page 5

PAGE 5

EXAMPLES OF FEATURES REQUIRING EDM OR BROACHING:

From left to right:

Tapered pocket with no radii requires EDM to produce

Straight side pocket with no corner radii requires EDM or broaching to produce.

When designing in any 3D modeling program, it is easy to get carried away with the simplicity of creating parts containing chamfers and

radii on every

edge, corner and face. But think about whether or not they are really necessary. Every feature added to a part also adds to the cost. It is

less expensive

to fillet a corner where two planes meet on a perpendicular plane. It is more expensive to fillet a face where the two planes contain

contours or are

not perpendicular, such as when an angular face and a perpendicular edge intersect. Be prepared to pay for the 3D machining

operations that will be

required to create those types of irregular features. In the case of intersecting holes we quite often see heavy internal fillets called for on

the edges

where these holes intersect. Often the only way this feature can be accommodated is by some sort of hand finishing. Only spec them in

if you

absolutely can not do without them.

Basic features:

When creating basic features such as drilled holes, depth and hole straightness will impact cost. Other considerations are very deep

holes with small

diameters, extreme straightness requirements, and off-center intersections with other holes or features. It is hard to say just when a

hole becomes

too deep for its diameter to make regular drilling impractical. Much depends on the nature of the material being drilled, and other

contributing

factors such as those mentioned above.

Irregular profiles on components are no longer the problem they used to be before the advent of CNC machines but there are still some

things to

consider when designing parts with such shapes.

One of the most important considerations for designing irregularly shaped parts is how the edge profile will be treated. Will it require a

fillet or

chamfer, or will it just be left sharp?